05 Apr Notice something different about our impact metrics?

As a social enterprise, FoodMesh is deeply invested in the social and environmental impact of our work. Our impact on the world is like a currency; it motivates decision making, product development and the efforts of our staff to make a meaningful difference in the world. To best understand it, we need to come up with a reliable set of measurements to quantify it. At FoodMesh, we measure our impact by using a series of values called ‘impact metrics’. These impact metrics include:

These metrics help put into perspective how big the issue of food waste is and how badly the world needs solutions to prevent, divert and better manage it.

You may have noticed that there has been a change in our impact metrics recently. That is because FoodMesh has changed how we estimate the CO2 emissions reduced, as well as the number of meals provided through our programs. Here’s why…

CO2 equivalents (CO2e) reduced

What exactly does CO2e mean?

When measuring greenhouse gas emissions, CO2 equivalents (CO2e) is most often used. CO2e is used to standardize greenhouse gasses such as CO2, methane, Nitrous Oxide etc. into one value. For example, 1KG of methane is equal to 25KG of CO2e.

To measure the reduction of CO2e, the CO2e is estimated for food that has gone to the highest end use (i.e. charity, farm feed, compost). This is subtracted from the estimated CO2e of the same food if it were to have gone to the status quo (landfill). The difference is the reduction potential of the food, which is measured in kilograms (KGs).

FoodMesh, diverts food from the status quo (usually landfill), to the highest end-use. Human consumption is the top priority, followed by farm feed and finally compost.

Previously, FoodMesh estimated CO2e reduction using a calculation derived from a 2017 study on food waste emissions by the Australian government. Aside from being outdated, this estimate did not take into account the unique environmental effects of different food types as well as their end-use (human consumption, animal feed, compost).

Our new estimate uses the same GHG reduction potential factors as the REfed insights engine, the highest standard for food waste data in North America. Each food type results in a unique amount of CO2e (meat and seafood, for example, create a lot more emissions than produce). To calculate our new estimate, the REfed emissions factors were mapped onto the grocery store departments that FoodMesh uses for donation tracking. Then, using real FoodMesh data, the CO2e reduced for each kilogram of food was calculated, dating back to 2018. Our new estimate of 2.58 KG CO2e reduced / KG diverted, is an average derived from more than 3 years of calculated values. This gives us a high degree of accuracy and allows us to better estimate the real difference between the status quo and the highest end-use.

By implementing these new estimates for CO2e reduced and meals provided, FoodMesh is more closely aligned with North American standards and has increased the accuracy of our impact metrics.

Meals provided

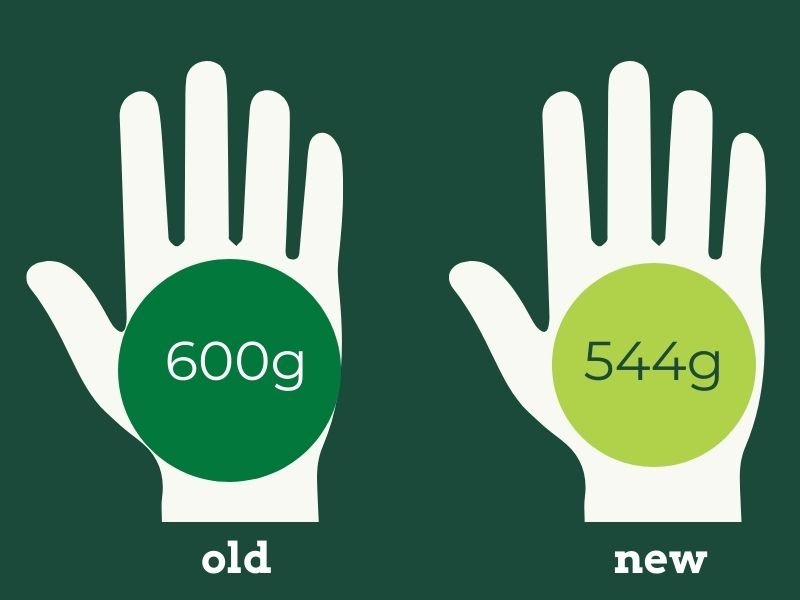

The meals provided metric is another estimate. It is based on the standard portion size of a North American meal. Previously 600g / meal was the standard, but has recently changed to 544g/meal or 1.2lbs / meal as seen in the REfed insights engine methodology.

By implementing these new estimates for CO2e reduced and meals provided, FoodMesh is more closely aligned with North American standards and has increased the accuracy of our impact metrics.

As of March 08, 2022, an estimated 40,000,000 KGs of CO2e emissions have been prevented from entering the atmosphere and an estimated 22,500,000 meals have been created as a result of FoodMesh programs.

To put that into perspective, that is enough meals to feed around 5,700 families, 3 meals a day, for an entire year; and the amount of CO2e sequestered by 73,000 hectares of forest for a year.

To learn more about our calculation methodology and our other impact metrics, visit our stats explained.

Written by Eric Douglas, Systems Analyst at FoodMesh